SABRE Rocket – Who and What is This Space Rocket?

There are many different rocket designs which are aiming to transform the space industry. These new concepts provide the prospect of space travel for millions of everyday people, rather than just for the specialist, highly trained astronaut or the mega rich few. Perhaps the most innovative and ground-breaking of these has plans to revolutionise the terrestrial travel industry too. And what’s more, it’s British!

Indeed, if you were to guess the location of a company whose mission it was to design a potentially game changing rocket engine, it is unlikely that a non-descript industrial park on the outskirts of Oxford would be the first place that came to mind. But it is indeed from just such an unlikely location that Reaction Engines are forging ahead with the design of their pioneering new SABRE engine.

SABRE Rocket Technical Background

All modern aircraft, like any that you’d use for a conventional Earth-bound flight, use jet engines. These are very powerful – capable of propelling a large aircraft with hundreds of passengers on board almost halfway across the world with relative ease. Or alternatively, powering a smaller aircraft at greater speeds: a military plane can reach velocities of around Mach 3 (three times the speed of sound). The problem for space travel is that jet engines require oxygen and air in order to be able to produce this power. This means that they can’t fly in space, which is a virtual vacuum.

Conventional passenger planes tend to fly at 35,000 feet. This is the optimum height for greatest economy: the air is thin enough to minimise resistance, yet thick enough to keep the aircraft’s wings aloft and provide thrust for the engines. Military aircraft are capable of flying much higher, although for obvious reasons these limits are often classified. The US SR-71 Blackbird has been recorded as flying at over 85,000 feet, and the iconic U2 spy plane is reputed to be able to fly even higher. However, it is likely that the laws of physics would prevent a winged plane flying much beyond 90,000 feet (about 17 miles) – there simply isn’t enough air at higher altitudes.

Rocket engines on the other hand, can travel much faster, and do not require air to work. This is why they are used for travel in space. They also provide much more power – essential for overcoming the Earth’s gravity and getting into space in the first place. Compared to conventional jet engines, they have a much higher thrust-to-weight ratio, but this comes at a price. The heavy, oxidiser-rich propellant required to achieve this power means that it simply isn’t efficient enough for Earth bound travel. They only become energy efficient at very high speeds and over long distances.

A New Solution from SABRE Rocket

Until now, this fundamental difference between jet and rocket power has meant that in general terms, jet engines are used on earth and rocket engines are used for space (both in space and getting there).

But Reaction Engines reckon that this could all be about to change, and their new SABRE engine design is at the forefront of this potential revolution. SABRE stands for Synergetic Air Breathing Rocket Engine, which is indeed an impressive acronym. But what does it mean?

In practical terms, the SABRE concept is a kind of hybrid engine. It uses both jet and rocket technology within the same unit, so that it will be able to function both on Earth and in space.

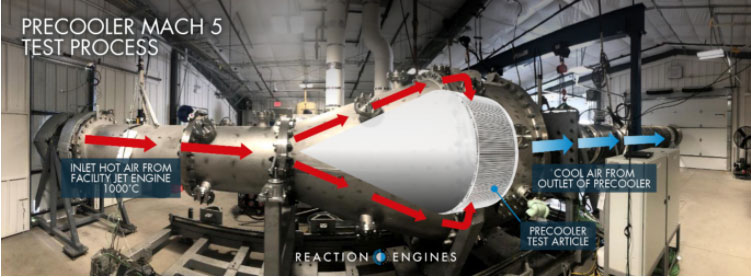

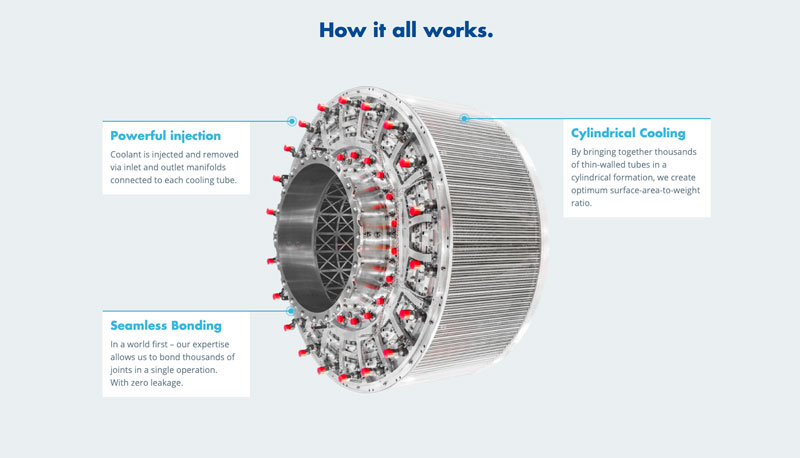

Conventional jet engines are unable to travel at speeds in excess of around Mach 3 because of the problem of heat. As speeds increase, the temperature of the compressed air in the engine increases to the point that it becomes too hot for the materials and metals used to build it to withstand. The engine would eventually become unstable as components began to fail and even melt. Reaction Engines overcome this problem by fitting a pre-cooler just behind the air intake cone. Super cold liquid hydrogen is recirculated to the air intake to cool the supersonic air from around 1,000°C down to -150°C in just one hundredth of a second. This super-cooled compressed air is then fed into the engine’s combustion chamber where it is ignited along with the stored liquid hydrogen fuel.

This cooler compressed air also enables the engine to achieve a far higher compression ratio, enabling a SABRE engine to produce more thrust, and hence higher speeds, at even higher altitudes than conventional jet engines. The lower air temperature also means that the engine can be constructed with more lightweight materials. This also makes the engines more efficient, and their lighter weight also makes it easier to progress into orbit if required.

The “hybrid” part comes into play as the engine reaches higher speeds and / or altitude. Once it reaches a speed of around Mach 5, or an altitude of about 93,000 feet, the air-breathing “jet” engine operation is discontinued. The air inlet is closed and the engine then operates in “rocket” mode, burning its on board liquid oxygen and hydrogen fuel to provide power. This configuration should allow speeds of over 17,000 mph (nearly 30,000 km per hour), the equivalent of Mach 25, when beyond the Earth’s atmosphere and in space.

Benefits of SABRE technology

The ability to use the same engine both in the air and in space offers clear advantages. Perhaps the most obvious from a space travel point of view is that it offers the opportunity to fly directly from a conventional runway into orbit. It improves access: potentially, future space tourists could be able to “catch a flight” into space from a conventional spaceport runway just as UK based passengers today fly from Heathrow or Stansted airports.

It also adds a whole new dimension to the concept of re-usable technology. Conventional rockets are usually a one off, disposable item. This is very expensive and wasteful. Even if they are technically re-usable, as SpaceX and Blue Origin’s rockets are intended to be, they have to be collected from the sea or returned to earth separately under their own power before they can be refurbished and then re-used. SABRE engine craft can simply take off and land like a conventional aircraft, requiring just a service before re-use.

This is clearly a far more flexible and cost effective system, not only for putting potential space tourists into orbit, but also for launching satellites and other technology too. It will become much easier and less expensive for businesses to get their technology into orbit when it is possible to book a flight just as you would to send cargo on a plane.

In more practical terms, perhaps the greatest advantage of the new engine in the short term will be its potential to make intercontinental travel much quicker. For example, by taking a more direct flight path, up into space and down again in a parabolic curve, a SABRE powered spaceplane should be able to complete a journey from Europe to Australia in around four hours.

When will we see SABRE engines in action?

If it all seems a bit fantasy sci-fi at the moment, the good news is that the SABRE engine is well on the way to reality. It is far beyond the theory and virtual drawing board stage and has already reached the production stage. Prototype engines have been built and early tests are very promising.

In April 2019, the engine’s pre-cooler unit was put through its paces in a ground firing test. A turbojet engine originally used to power an F-4 Phantom was used to feed air into the pre-cooler unit at the equivalent of Mach 3.3. The unit passed with flying colours, cooling the engine’s thrust gases down from 420°C in just 1/20th of a second.

As for when we will actually see any planes powered by SABRE hybrid engines actually take flight, it is difficult to be sure. Testing has gone well and all the indications are that it is a practical design which is likely to make it to the production line.

It is a British design though. Americans like to be confident and assertive in their predictions – promising tests and launches which then tend to be put back. British companies prefer the more understated, less PR oriented approach (Sir Richard Branson aside), so no firm dates have been promised by Reaction Engines at the time of writing.

Nevertheless, the outlook seems very bright, with progress consistent and plenty of funding and investment in place. It’s looking like some production model engines could arrive in the early 2020s. It therefore looks reasonable to expect some test flights by the mid-2020s, with commercial flights following by the end of the decade.